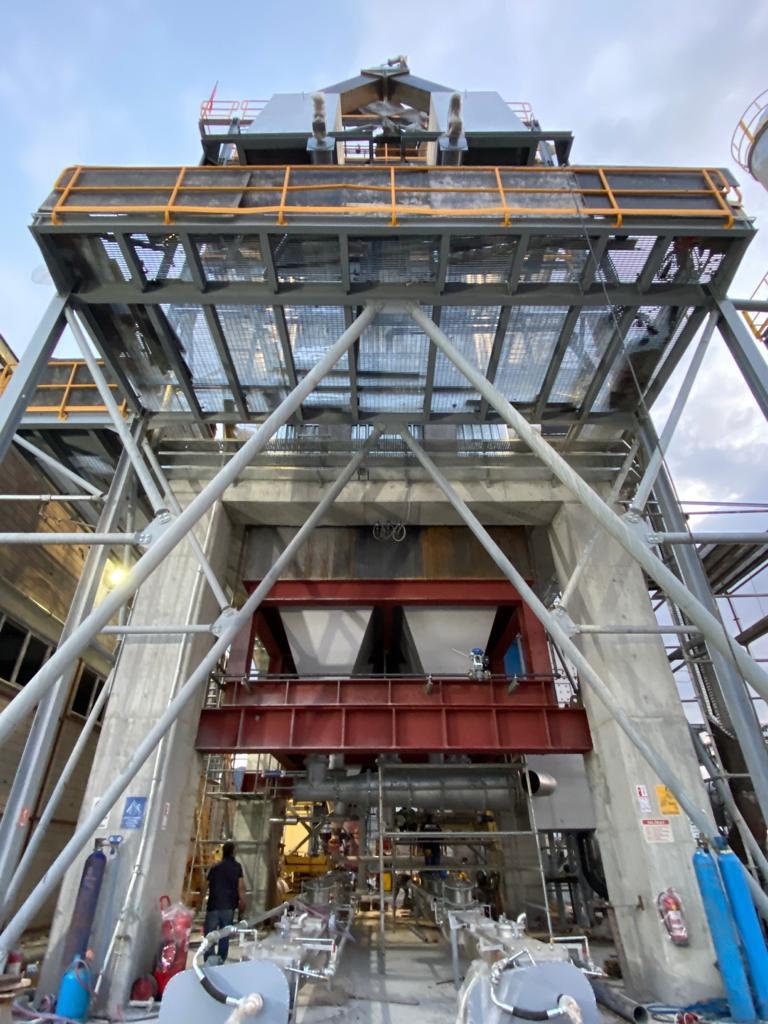

Fluidized Bed Boilers

Depending on technical parameters and customer demands, Eralp can use combustion system design as Bubbling Fluidized Bed (BFB),German patented Twinfluid Technology or Circulating Type Fluidized Bed (CFB).

In BFB boilersthe velocity of the combustion air is low enough that the fluidized particles remain in the lower furnace; in a CFB unitthe velocity is greater and hot particles are circulated through the entire range of the boiler combustion zone.

The fuel is in contact with the particles and effective mixing.

CFB is especially suitable for large boiler and load ranges.

In Twinfluid Technology,the fluidized bed system is designed side by side with a shallow bed and heat transfer bed required for combustion. By controlling the exchange of solids between the two fluidized beds, it is possible to set up heat extraction from the combustion process. In the Twinfluid bed system, at low gas velocities, the furnace height is reduced, and the required suspension time is reached. Therefore, the furnace has a more cubic and compact structure than conventional CFB type.

PRODUCTION CAPACITY

Steam Production Capacity: 15 tons/h -200 tons/h

Pressure: 60 Bar

Temperature: Max 500 C

PRODUCTION STANDARD

Fluidized Bed Boiler production is carried out in accordance with EN 12952 standards and 2014/68 EU Pressure Equipment Directive Module G and is produced with CE Certificate. If desired, thanks to our existing certificates, production can be made in accordance with ASME Part I and with “S” stamp.