Economizers

GENERAL INFORMATION

Economizers are a type of water tube heat exchangers used in heat, steam or power production facilities to recover some of the heat contained in the flue gas of the boilers and going to the chimney.

The economizers that transfer the flue gas heat to the boiler feed water are called “Feed Water Economizer“, the economizers that are transferred to the domestic water (bath-shower, process washing, etc.) are called “Hot Water Economizer“, and the economizers that are transferred to the inlet air of the burner are called “Hot Air Economizer“.

When use less fuel for needed requirements CO emission is reducing . As Eralp Boiler ,With using economizer in our system we reduce fuel consumption and CO emission .

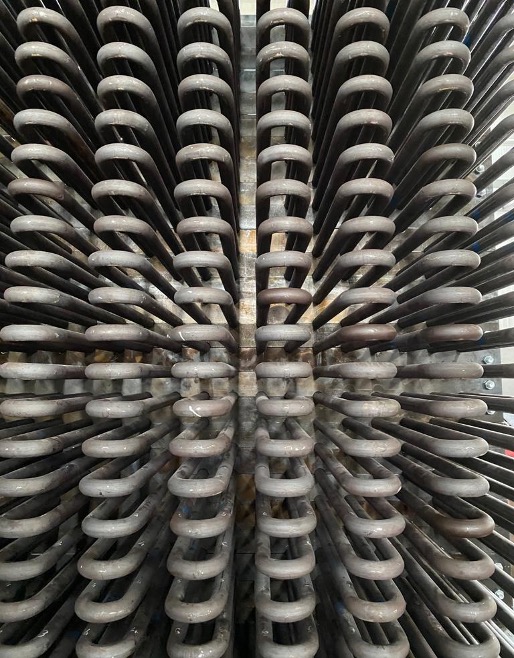

PRODUCTION

Economizer gas outlet temperature can be reduced to 180˚C in heavy fuel oil fired boilers, 160˚C in diesel fired boilers, and 110˚C in natural gas and LPG fired boilers due to dew point . In natural gas fired boilers, it can be reduced to 50˚C in condensing systems.

Depending on the boiler flue gas outlet temperature, fuel type and the number of economizers to be installed, total efficiancy can increase between 3% and 8% with using economizers

Economizers investment return period is between 5 to 20 months according to type of economizers .

As Eralp Boiler we use “High Frequency Welded Finned Pipe” to increase heating surface in economizer , which is also used in Natural Gas Cycle Power Plants too. We supply fintubes from Eralp Fintube group company who has first and only manufacturer of frequency welded fintube in Turkey since 2008 .

We use a European seamless tube in our bare or fintube with EN 10204 3.1 certificate.

We are available to design and manufacture two economizer (Boiler feed Water + Hot air Ekonomizer etc ) in single body which is called Combi Economizer. Low price and reducing installation space is some advantages of this design .

PRODUCTION STANDARD

Behind the boiler producing steam up to 300 tons/hour